Gas Chromatography

Crystal 9000 is a high-end gas chromatography system created to meet all challenges. The original design of the system’s components offers a universal platform to reach maximum flexibility and efficiency.

KEY FEATURES

Gas Flow & Pressure control: Unified Electronic Pneumatic System (UEPC)

Maximum total flow: 1250 mL/min for any gas

Oven temperature range: up to 450 °С with unlimited number or ramps

Pressure control setpoint resolution: 0.01 kPa / 0.001 psi

Number of inlet/detectors simultaneously: 3 inlets / 4 detectors

Detector range: FID, NPD, ECD, FPD, PFPD, TCD, PID, CCD. PDD, SCD, MSD

Inlets available: Packed, Split/splitless, Programmable Split/splitless (PTV)

Retention time repeatability: < 0.008 min

Mass Spectrometry

Chromatec’s unique GC/MS solutions offer both unsurpassed sensitivity an unparalleled stability for a wide range of applications in any laboratory. The system can deliver high-performance, throughtput and accuracy.

Sample Introduction Systems

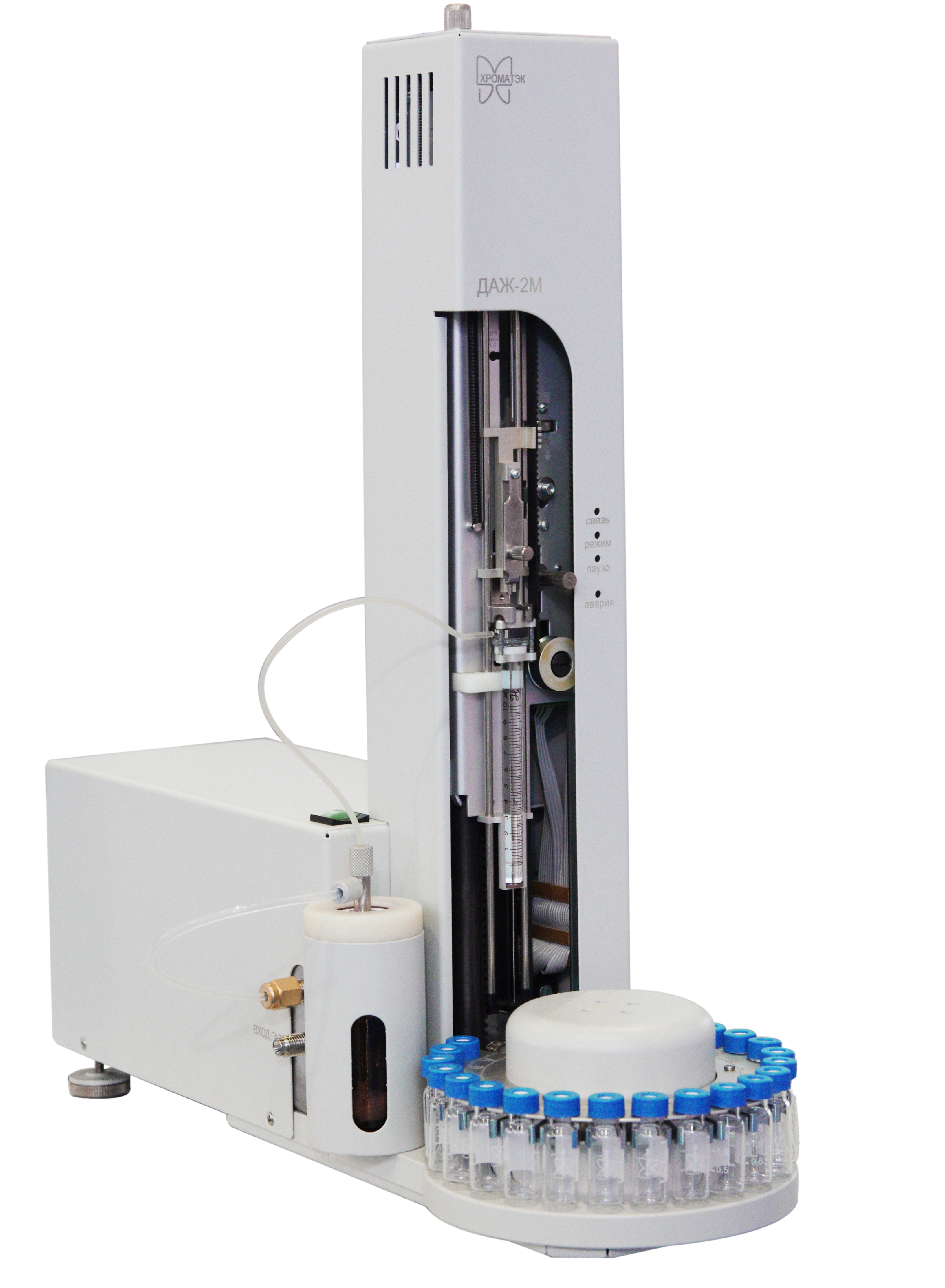

AS-2M single port

Autosampler 3D headspace

Autosampler implements static headspace technique by syringe.

Manual Headspace system

TDS 2 stage manual

TDS 450

Cool on-column injection mode

Very low cooling agent consumption for cryo-trap

Gas Generators

Clean Air Generator

Intended for producing compressed air to feed flame detectors (FID, FPD, NPD). Chromatec compressor has very strong points: low noise level and stable output pressure.

Hydrogen Generator

Intended for producing hydrogen from distilled water and allows to substitute hazardous in use hydrogen gas cylinders, to feed flame detectors (FID, FPD, NPD) as well as carrier gas.

Catalytic Filter

Intended for gas cleaning from oxygen and organic impurities by heating in the presence of catalyst. Especially used to feed ECD detectors or working with WAX or FFAP column types.